ONSITE SPECIALTY TOOLMAKERS SERVICES INC. was created to allow anyone access to the highest levels of toolmakers and their abilities. We offer a multiple trade solution to manufacturing downtime available to anyone, anywhere, on their premises. Our skills allow us to design, customize, modify and repair any type of commercial, industrial and residential equipment and/or tooling. Our certified tradesmen can accomplish the repair and modification of equipment in a matter of hours on location rather than costly shipping and downtime.

Precision Welding of Any Material

ONSITE SPECIALTY TOOLMAKERS INC. is comprised of only the highest level Toolmakers with years of experience in multiple fields and levels of training in areas not regularly done by anyone else.

Our Toolmakers will match any texture or graining along with the finish blasting to make any repair invisible.

There are no limits to our abilities in finishing surfaces of any alloy under any circumstances.

Our Toolmakers are devoted to saving your company the downtime, shipping costs and expense of acid etching repair by completing any job onsite.

Bolt Thread Repair

Any material, any size, any level of detail all welded on your premises with our own equipment reducing your downtime and shipping costs exponentially.

High Detail Functional Repair

Ferrous, non-ferrous, specialty aerospace alloys, hardened tool alloys, stainless steel and cobalt alloys, hard facing, all bronze and aluminum alloys

Any Level of Detail

Any style grain or texture repaired on your premises no matter how extensive the damage.

24 Hour Emergency Services Available

Contact Us at Any Time

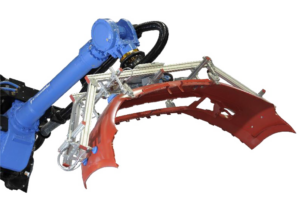

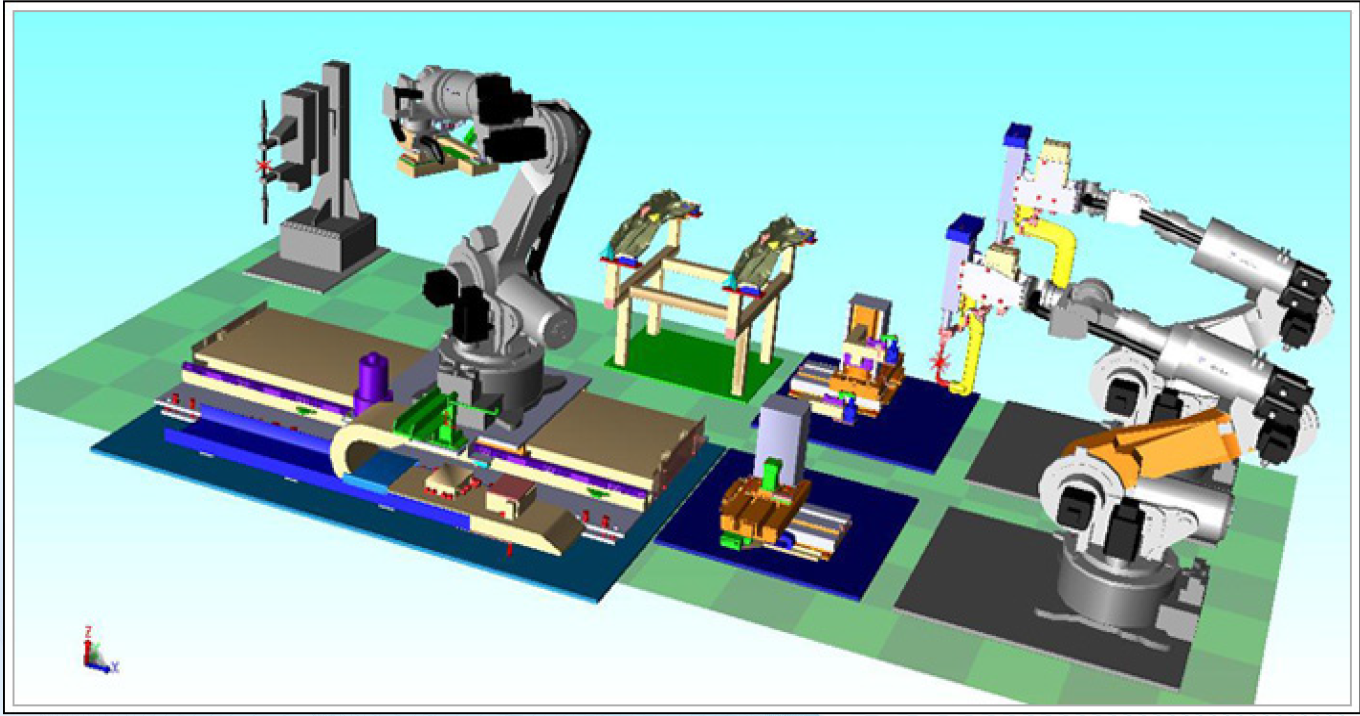

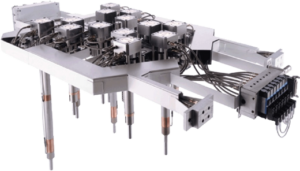

Automation Robotics and End of Arm Tooling

Onsite Specialty Toolmakers Services Inc. can design and build any automated cell from beginning to

end.

Our Toolmakers have the knowledge and experience in multiple fields to

use every available technology.

This allows your company to increase production,

reduce costs and create work cells with the highest level of efficiency possible.

We Deliver Expert Solutions

Industrial automation systems and enable customers to operate more effectively and efficiently without the worry of obsolescence. We have the expertise to offer designing, building, programming and interfacing intricate robotic cells. We can help in manufacturing automated systems, robotic automation, automation control and in many other automated applications within the automation industry.

Design Re-engineer

Modify, repair, build, program and initiate any end of arm tooling or secondary equipement.

Years of Experience

We have the expertise to offer designing, building, programming and interfacing intricate robotic cells. We can help in manufacturing automated systems, robotic automation, automation control and in many other automated applications within the automation industry.

Onsite Services

Whether your need is basic or complex, OST Services Inc. has you covered.

Precision Welding

Texture Repair / Polishing

Process Improvements

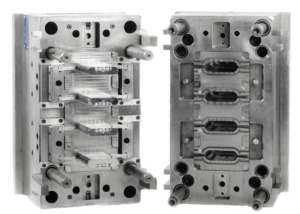

SVG and Hot Runner Repair

Fitting / Spotting

Fabrication

Electrical / Hydraulics / Pneumatics

Cycle Time Reduction Improvements

Preventative Maintenance

Free Estimates

Stamping and Progressive Dies

Full 3D Design Services

Our certified toolmakers can be the difference needed to compete in the global market. One of our toolmakers coming to your premises with the knowledge of years of experience in all types of manufacturing will give your company the accuracy level and production speed necessary to compete on a global level.

Automation

OST Automation is industry leading in creating solutions for improving productivity. OST Automation is a company with extensive experience and unique know-how in industrial automation and turnkey engineered solutions for the industry. Our experts have designed and built over twenty custom automation cells in fields such as quality assurance, assembly, insertion equipment and material handling systems. Our broad experience in various industries and use of proven original techniques helps us to offer unique solutions to our customer's manufacturing challenges. We supply mainly to automotive industry and are specialized in de-moulding and secondary operations like clip insertion, de-gating and quality assurance using vision systems. Our experience and expertise in designing, developing and building high-quality cost-effective automated solutions can provide anyone with the competitive advantage needed to compete in the global market.

QUALITY, PRECISION AND ACCURACY

Our level of tooling and automation knowledge combined with precision TIG welding skills allow us to perform repairs and modifications to many types of tooling, secondary equipment, fixtures and quality assurance gauges.

Injection Mould Texture Repair and Polishing

ONSITE SPECIALTY TOOLMAKERS INC. is comprised

of only the highest level Toolmakers with

years of experience in multiple fields and levels of

training in areas not regularly done by anyone else.

Our Toolmakers will match any texture or graining

along with the finish blasting to make any repair

invisible.

There are no limits to our abilities in finishing surfaces

of any alloy under any circumstances.

Our Toolmakers are devoted to saving your company

the downtime, shipping costs and expense of

acid etching repair by completing any job onsite.

Before

After

24 HOUR EMERGENCY SERVICES AVAILABLE

Our certified toolmakers can be the difference needed to compete in the global market. One of our toolmakers coming to your premises with the knowledge of years of expereience in all types of manufacturing will give your company the accuracy level and production speed necessary to compete on a global level.

TEXTURE REPAIR, PRECISION HANDWORK AND POLISHING

PRECISION TIG WELDING WITHOUT AFFECTING DIMENSIONS

SEQUENTIAL VALVE GATE AND HOT RUNNER SYSTEM REPAIRS

Onsite Specialty Toolmakers Services Inc

Onsite Specialty Toolmakers Services Inc